Bright Machines is going public via a SPAC-led merge, it announced today. The transaction will see all 3-year-old company merge alongside SCVX, raising gross tough proceeds of $435 shades in the process.

Once the transaction is consummated, you see, the startup will sport any anticipated equity valuation because of $1. 6 billion.

The Bright Systems news indicates that the superb SPAC chill was not a meaningful deep freeze. And the transaction its own costs, in conjunction with the previously announced Counter top Metal blank-check deal, implies that there is space in the market for parts startup liquidity via SPACs. Perhaps that will unlock added late-stage capital for hardware-focused upstarts.

In our day we’re first looking at the Bright Machines does, after that the financial details this is shared as part of its news reports.

What’s Next to Machines?

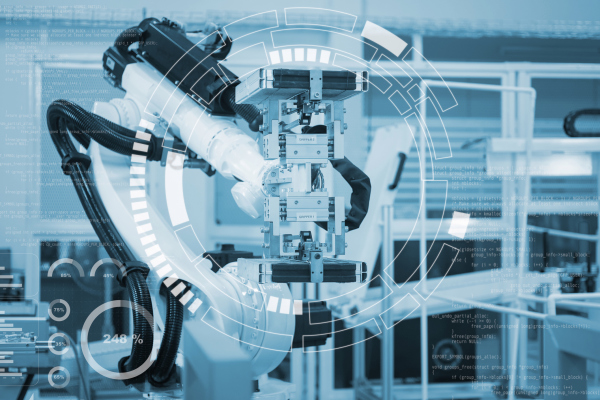

Idealistic Machines is trying to solve an overwhelming problem related to industrial automation of tasks by creating microfactories. This calls for a complex mix of hardware, computer programs and artificial intelligence. Although robotics has been around in one system or another since the 1970s, basically, it has lacked real learning ability. Bright Machines wants to transform that.

This company emerged in 2018 combined with a definite $179 million Series An absolute , a hefty amount of money for a young startup, nevertheless company has a bold thought and such a vision offers extensive funding. What it is a trying to do is completely improve manufacturing using machine being familiar with.

At the time of that a lot of funding, the company brought in first Autodesk co-CEO Amar Hanspal as CEO and previous Autodesk founder and BOSS Carl Bass to sit on the company board of directors. AutoDesk itself has been hunting to transform design and assembly in recent years, so it was realistic to bring these two experienced emperors into the fold.

The startup’s thesis is due to the fact that instead of having what are in reality “unintelligent” robots, it to be able to add computer vision plus heavy dose of sensors to bring a data-driven automation approach to the factory floor.