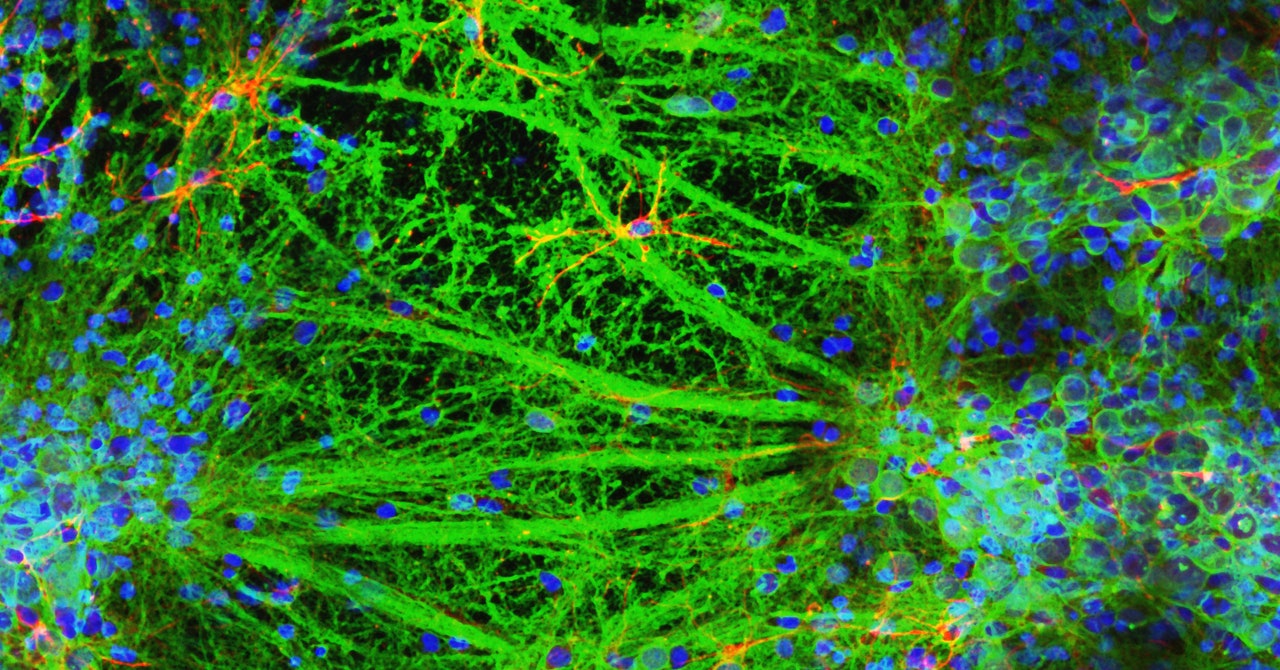

A tiny array of microelectrodes underneath the cells recorded electrical activity in the gel surrounding the cells, while other electrodes directly stimulated the neurons and recorded their responses. Using a fluorescent dye to visualize the movement of calcium ions under a microscope, the team was able to watch the cells chemically communicate. “They behaved as we would expect,” Forsythe says. “There were no surprises.”

While it may not be surprising that these neurons behaved like, well, neurons, it’s a big deal. When it comes to potential biomedical applications like drug discovery and studying neurodegenerative diseases, neural networks are only as valuable as they are functional.

That starts by making sure you don’t kill the cells when you print them. When standard 3D-printers work with plastic filaments, they melt the plastic to make it moldable, heating it up to temperatures far beyond those found in the human body. This is a nonstarter for neurons, extremely finicky cells that can survive only in carefully calibrated gels that closely replicate properties of squishy, body-temperature brains. “Making a gel that is as soft as the brain, but that you can still print through a 3D-printer, is really hard,” says Moore.

“It’s important not to kill the cells. But with neurons, it’s really important not to kill your electrical activity,” adds Stephanie Willerth, a professor of biomedical engineering at the University of Victoria in Canada, who was not involved in this study. Earlier versions of 3D-printed neural tissue often excluded glial cells, which help maintain a welcoming environment for their sensitive neuron neighbors. Without them, “neurons still have some electrical activity, but it’s not going to fully replicate what you see in the body,” she says.

Willerth thinks the new experiment is promising. These neural networks were made of rat cells, but “it’s a proof of concept showing that you can eventually do this with human cells,” Willerth says. Still, future experiments will need to replicate this level of function in human cells before these neural network models can be used in translational research and medicine.

There is also a scaling issue. The tissues printed in the Monash experiment contained a few thousand neurons per square millimeter, amounting to a couple hundred thousand cells in each 8 x 8 x 0.4 mm structure. But the human brain has about 16 billion neurons in the cortex alone, not to mention billions more glial cells.

As Moore points out, 3D-printing such delicate tissue is relatively slow, even when the final product is tiny. More work needs to be done before this precise but sluggish technique can be scaled up from academic research labs to Big Pharma, where companies are often testing dozens of drugs at once. “It’s not impossible,” Moore says. “It’s just going to be difficult.” (AxoSim, a neuroengineering startup cofounded by Moore, has already started building 3D models of human neurons and peripheral nerves for commercial drug testing.)

While this technology has the potential to replace animals in many research settings, from basic neuroscience to commercial drug development, scientists may be slow to make the switch. Often, Moore finds, scientists like him are “stuck in our ways,” reluctant to spend the time, money, and effort required to move away from tried-and-true animal models. “Convincing scientists to abandon those approaches for fancy engineered tissue is going to take time,” he says, “but I’m very optimistic that we will gradually reduce the number of animal studies.”